Breaking Down the Anatomy of a Coffee Cherry

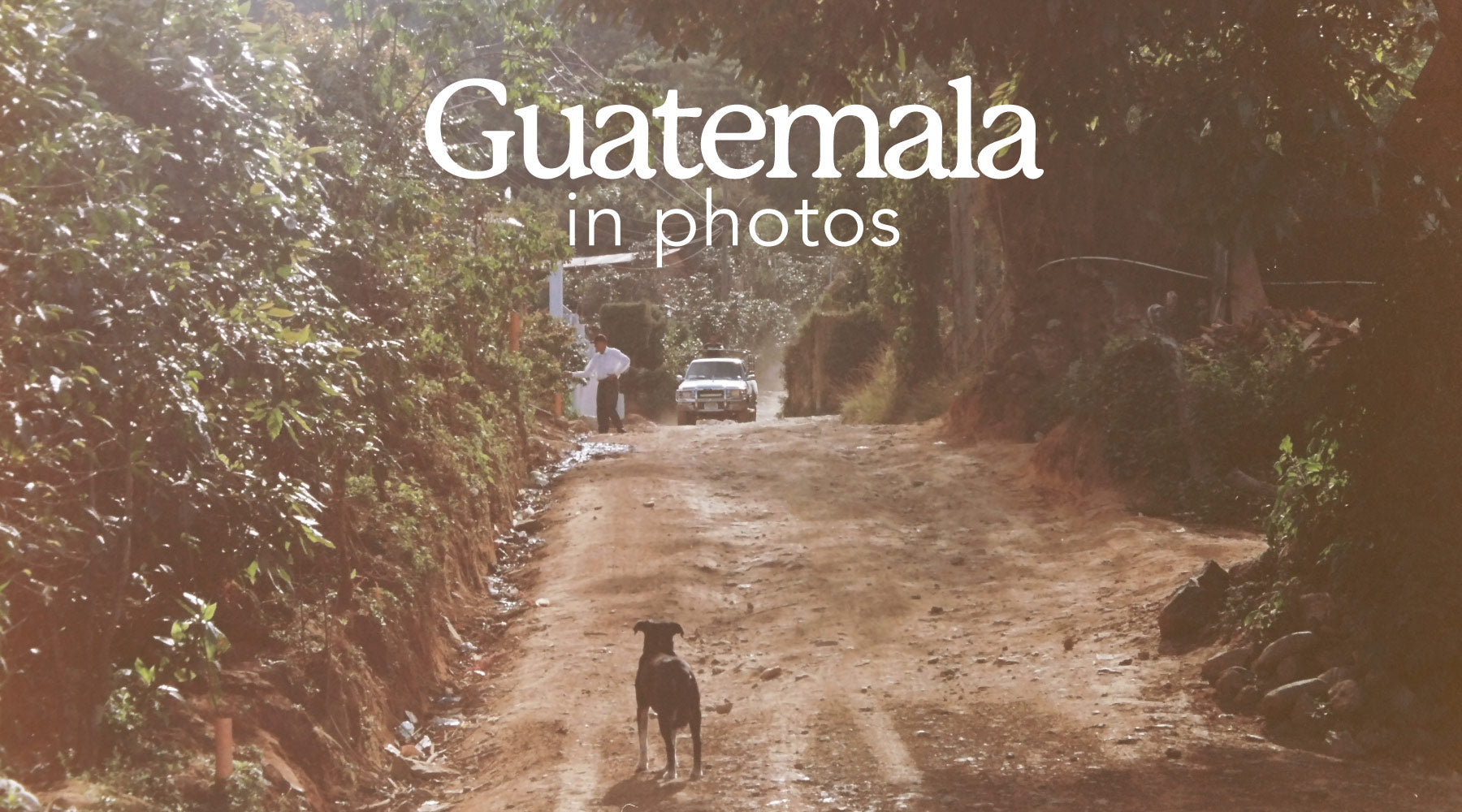

When I visited Guatemala on an origin trip in early March of 2022, one of the most helpful educational takeaways came from simply being able to tangibly interact with the coffee cherry itself. Sure, I’ve seen millions of processed green coffee beans in my lifetime, but this was the first time I’ve been up close and personal with an actual coffee tree producing ripe coffee cherries. The experience was really eye-opening. The coffee fruit was super delicious, although there wasn’t much of it since the coffee plants have been cultivated and bred to maximize the bean size, not the fruit size. What was there was a delectable little burst of natural sweetness. As I spat out the outer skin of the cherry, it was truly interesting to see all the dots around how coffee processing works begin to connect. I immediately had a firmer understanding of every aspect regarding how a coffee bean went from a cherry to a roasted bean.

I hope that with this quick breakdown of the anatomy of a coffee bean, I can help bridge that gap for you a bit, so you don’t have to spend a week in rural Huehuetenango to understand the critical correlation to a coffee cherry’s anatomy and how that cherry is processed. Understanding the anatomy of the coffee cherry helps us take a step back and garner an appreciation for the craft of each and every step in the coffee process. There is a lot of unseen work that goes into getting that morning cup of coffee, and the more we know about the complexity of the coffee plant, the more we will realize the complexity of the coffee industry.

The Steps of the Washed Process

Like any fruit, it is crucial for coffee to be picked in its proper window of ripeness, otherwise, the final product of the coffee bean will be entirely underdeveloped, sour, and earthy. For coffee, this window is between 3-7 days.

Many farms that are not focused on the quality of the coffee would likely be ok with picking coffee fruit of this ripeness level, but this will not reap the full sweetness potential that the coffee cherry can achieve.

This is the prime ripeness level of the coffee cherry; at this point in its development, coffee pickers will pluck this fruit from the coffee tree and will process this fruit at the end of the picking season.

Coffee farms will use certain methods such as soaking the fruit in water or hand sorting the visually inconsistent fruits out to further narrow down the selection of the best coffee cherries. Once sorted, the cherry peel is then removed.

Now that the skin of the coffee cherry is removed, what’s left is the cherry pulp, also known as mucilage. This outer sticky substance gives the processing center a lot of different opportunities for what direction they want to take the flavor profile of their bean. For this example, we’ll stick with the washed process, but many different forms of fermentation can take place, which will subsequently result in a different processed coffee. Examples include semi-washed, red honey, yellow honey, black honey, and washed fermentation.

As the processing is taking place, an eye is kept out for inconsistent or overly ripe beans. At this point, these beans are sorted out and disposed of.

The actual fruit substance of the coffee cherry is officially out of the way now. At this point, the coffee is laid out in the sun to dry. As the beans sit, workers will continuously shift the spread pile of beans, so the sun doesn't cook them because we just want the moisture out of the system, we don’t actually want any cooking to take place. From here, processors can fully focus on singling out the finalized coffee bean. There is still an outer pistachio-like shell on the bean called the “parchment” that must be removed.

The equipment to properly mill coffee is usually too expensive for small farms to be able to invest in themselves, so the coffee milling process is often outsourced to a central coffee mill somewhere in the region. In the coffee mill, the dried outer layer of the seed known as the “parchment” is separated from the inner coffee bean and disposed of. The coffee mill is a critically underrated part of the coffee process. It’s not often discussed as the central point of the coffee process, but it is indeed a balanced combination of taking in the harvested beans from farms, bringing the beans to a final and uniform product, and leading the process of transporting the beans either directly to local roasters or international distributors.

After the parchment has been removed and the inner bean has been exposed, it’s now time to evaluate a proper consistency across the coffee beans. Metrics and measurements take place to judge a coffee’s size, weight, and color. This sorting takes place in order to create the most “roastable” batch of coffee with the harvest that the coffee mill has brought in. If there is a stark inconsistency of any of these three factors, then a batch of this coffee will not be able to properly put on display the natural flavor notes of the coffee bean.

To lengthen an unroasted coffee’s shelf life, fully processed beans are usually set aside to rest and settle before they undergo international shipment. This allows for more effective and trustworthy coffee that can maintain the same flavor profile it’s developed in processing for elongated amounts of time. Typically, the shelf life of specialty coffee ranges from 4-12 months, depending on the process.

Roasting the coffee bean is a crucial point in the process. If done poorly, then all the work that came before the roaster to get the coffee bean the way it is could be ruined. It is crucial for roasters to dial in their practices to put on display the craft and artistry of each & every step of the coffee process. This is why we here at Sagebrush Coffee are so dedicated to accentuating the entire coffee process. The more we learn about the world of coffee, the smaller we feel as a coffee roaster. We're simply just passing the torch along to you, the coffee drinker.